Leveraging Circular Economy Principles for Sustainable Procurement ♻️

Article by Megan Colbeck, Consultant at Equipoise

The traditional procurement process has long focused solely on cost, quality, and availability. With increasing pressure from consumers and stakeholders to prioritise sustainability, more and more organisations are beginning to understand the importance of sustainable procurement. When it comes to sustainability, one approach that stands out is leveraging circular economy principles.

In this article, we’ll explore why circular procurement is a smart choice for organisations looking to make a positive impact on the environment, society, and their bottom line.

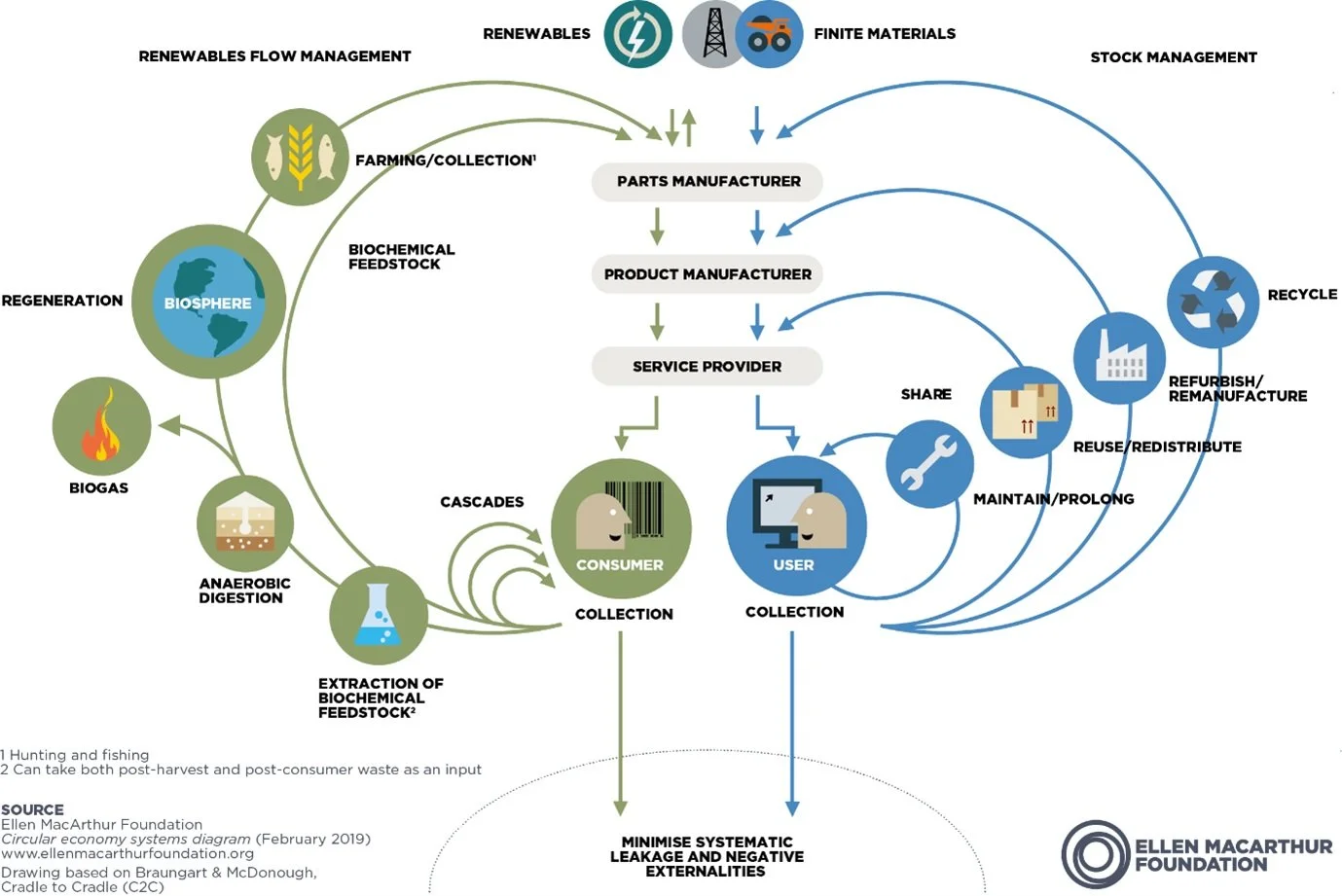

In a circular economy, resources are kept in use for as long as possible, maximising their value and minimising waste this is achieved by designing products to be reused, refurbished, and recycled. In contrast, the linear ‘end-of-life’ economic model is based on the 'take-make-dispose' approach, where products are created, used, and then disposed of at the end of their life [1].

This video from the Ellen MacArthur Foundation circular economy principles are explained in more detail:

The Value of Circular Procurement:

The circular model offers a more sustainable way of doing business and can bring significant financial benefits.

Environmental impact. By prioritising sustainable materials and packaging, organisations can minimise their carbon footprint, reduce waste, and conserve resources. This is not only good for the planet, but it can also help companies meet their sustainability goals and enhance their reputation among consumers and stakeholders. For example, in 2019, Adidas launched a range of sustainable trainers made from recycled ocean plastic with Parley for the Oceans. They created a closed-loop system for production were they collected plastic waste from beaches and coastal communities, recycled it, and used it to make trainers. By adopting this circular procurement approach, Adidas reduced its environmental impact, sold out days after the shoe launch and enhanced its reputation among consumers.

Cost savings. Organisations can reduce their costs and increase efficiency by using sustainable materials and packaging. Electronics company Philips has implemented a circular procurement program that aims to reduce waste and conserve resources by sourcing materials and products that are designed for circularity [2]. As part of this program, Philips worked with suppliers to identify materials that could be recycled or reused in their products. By implementing this program, Philips has reduced its material consumption by 4% and achieved a cost savings of €34 million. Adopting circular economics principles can lead to significant business benefits, including reduced environmental impact and increased cost savings.

Applying Circular Economy Principles to Procurement:

1. Designing for circularity: Designing products and materials with the end of life in mind for resource retention [3]. By designing for circularity, organisations can ensure that the goods they buy are easy to repair, upgrade, and recycle. This not only reduces waste and conserves resources but can also create new business opportunities, such as selling recycled materials or offering repair and upgrade services. Dell, the computer manufacturer, has implemented this by designing products for disassembly and reuse [4]. The company has implemented a closed-loop recycling system allowing them to recover valuable materials from used products for reuse.

To implement this principle, procurement can work with designers and suppliers to incorporate circularity into product and material design and consider the entire lifecycle of a product, from sourcing to disposal.

2. Zero waste mindset: Eliminate waste at every stage of the supply chain and ensure that resources are kept in use for as long as possible. This can include reducing waste during production, minimising packaging waste, and implementing efficient waste management practices. A zero waste mindset not only helps reduce environmental impact but can also save organisations money by reducing material and disposal costs. Unilever, the consumer goods company, has implemented a zero-waste mindset by adopting a circular economy approach to its packaging [5]. The company has set ambitious targets to eliminate waste from its production processes and to use only sustainable packaging materials. By adopting this strategy, Unilever has reduced waste disposal per tonne of production by 96% since 2008.

To implement this principle, procurement can conduct waste audits, set reduction targets, and implement waste reduction strategies such as composting, recycling, and repurposing.

3. Embracing the sharing economy: Sharing resources and assets to reduce waste and increase efficiency. By sharing resources, organisations can reduce the need for new products and materials, lower their carbon footprint, and create new revenue streams. For example, organisations can share office space, vehicles, and equipment with other organisations, or implement a product-as-a-service model where customers pay for access to a product rather than owning it outright. For example, Zipcar is a UK car-sharing service that allows drivers to rent cars on an hourly basis and is used by over 14,000 organisations [6]. By sharing cars, Zipcar reduces the need for companies to own their own vehicles and increases vehicle utilisation, which leads to cost savings and reduced carbon emissions.

To implement this principle, procurement can explore sharing partnerships with other organisations, or implement a sharing platform or program for their own assets.

In conclusion, leveraging circular economy principles offers a powerful approach to sustainable procurement that can benefit organisations in multiple ways. By prioritising sustainable materials, packaging, and suppliers, organisations can reduce their environmental impact, reduce costs, enhance their reputation, and improve their bottom line. Procurement and sustainability leaders should consider the three circular economy principles discussed to successfully implement circular procurement. By taking these steps, organisations can make a positive impact on the environment and society, while also creating long-term value for their stakeholders.

-

Organisations can positively impact both the environment and their bottom line by adopting sustainable procurement practices.

By integrating circular economy principles into procurement - designing for circularity, fostering a zero waste mindset, and embracing the sharing economy - organisations can maximise resource value, minimise waste, and realize cost savings.

Success stories like those of Adidas, Philips, Dell, Unilever, and Zipcar show that Circular Procurement can reduce environmental impact and enhance a company's reputation, underscoring its viability as a future-forward business strategy.

Want a simple 6-step guide to get started with Circular Procurement?

References

1. Kirchherr, J., Reike, D. and Hekkert, M., 2017. Conceptualizing the circular economy: An analysis of 114 definitions. Resources, conservation and recycling, 127, pp.221-232.

2. Philips. The circular imperative. Available at: https://www.philips.com/a-w/about/environmental-social-governance/environmental/circular-economy.html

3. Reike, D., Vermeulen, W.J. and Witjes, S., 2018. The circular economy: new or refurbished as CE 3.0?—exploring controversies in the conceptualization of the circular economy through a focus on history and resource value retention options. Resources, conservation and recycling, 135, pp.246-264.

4. Dell. Accelerating the circular economy to reduce waste ad protect the planet. Available at: https://www.dell.com/en-us/dt/corporate/social-impact/advancing-sustainability/accelerating-the-circular-economy.htm

5. Unilever. Tackling manufacturing waste. Available at:https://www.unilever.com/planet-and-society/waste-free-world/tackling-manufacturing-waste/

6. Zipcar. How the Sharing Economy is Enabling Smarter Working. Available at: https://www.zipcar.com/en-gb/blog/business/sharing-economy-smarter-working